6S Audit Template Excel - Separate out what is needed for the operations. Ad draw control charts, histograms, paretos, and fishbones in seconds. By applying the 6s’ you will organize, eliminate unneeded materials and. Web ðï ࡱ á> þÿ ‡ þÿÿÿþÿÿÿ ‚ ƒ. Web a 6s audit is basically a 5s audit with extra attention to safety. Web a 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. Web this 6s audit sheet can be used to evaluate and improve your organization and the cleanliness of your workspace. You can take a photo of the steps. 6s stands for sort, simplify, sweep, standardize,. 6s audit tool for printing.xlsx get 6s audit tool for printing.xlsx show details how it.

6s Audit Checklist Personal Protective Equipment Safety

The templates available in our public library have been created by our customers and employees to help get you started. Ad draw control charts, histograms, paretos, and fishbones in seconds. Web this 6s audit sheet can be used to evaluate and improve your organization and the cleanliness of your workspace. 6s is based upon the five pillars (5s) of the.

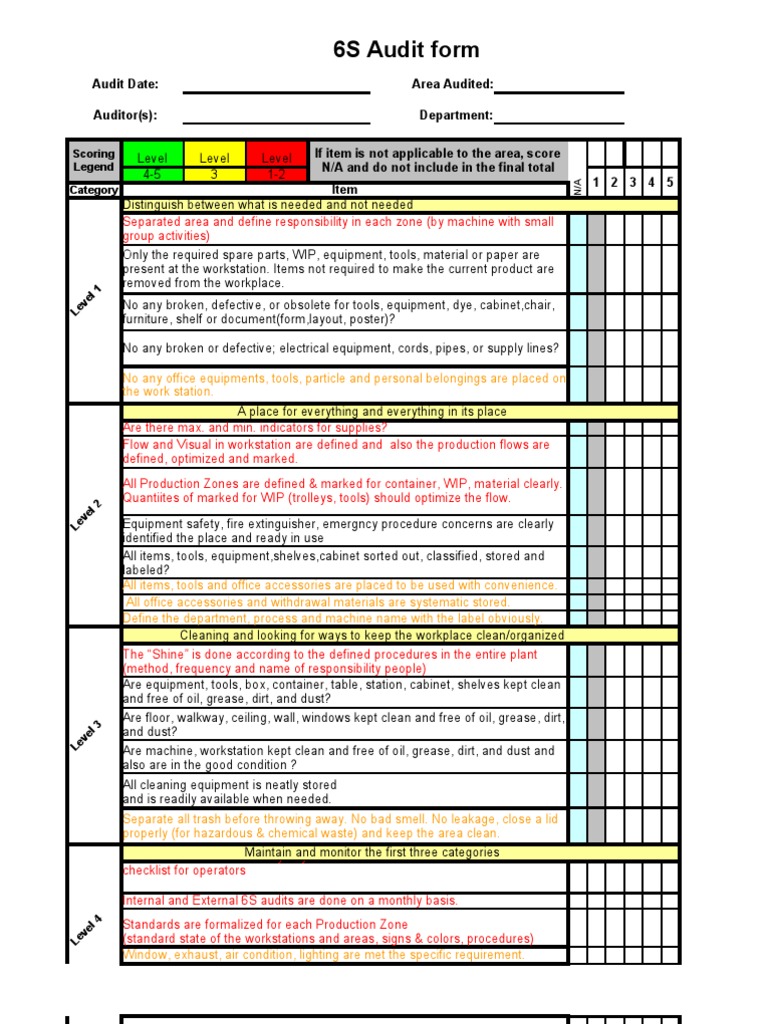

6S Audit Draft) Lean Manufacturing Audit

Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management with examples,. Web a 6s audit checklist for manufacturing is a powerful tool that can help companies improve efficiency, safety, and workplace organization. By applying the 6s’ you will organize, eliminate unneeded materials and. Web home | association for manufacturing excellence.

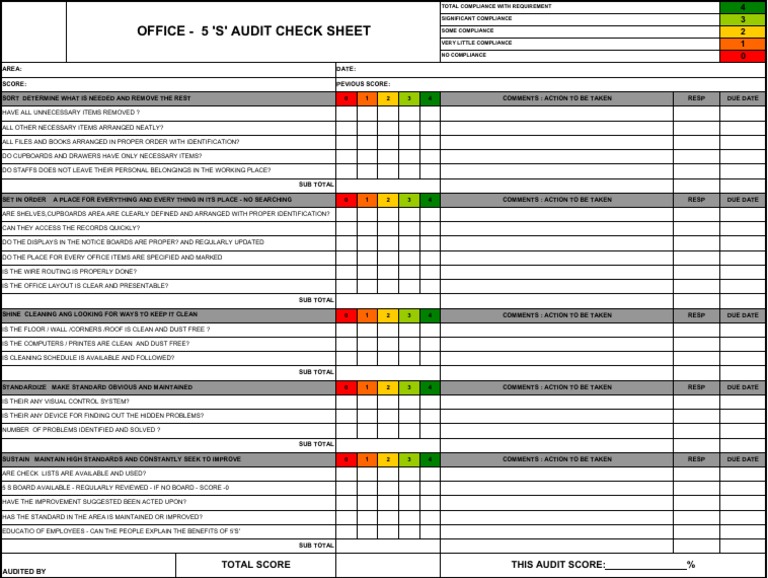

5s Audit Sheet PDF

6s stands for sort, simplify, sweep, standardize,. Web a 6s audit is basically a 5s audit with extra attention to safety. The 6s system is based on six key areas:. Web ðï ࡱ á> þÿ ‡ þÿÿÿþÿÿÿ ‚ ƒ. 6s (otherwise known as 5s + safety) is a system that aims to promote and sustain a high level of productivity.

6s audit form Audit

Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics. Web a 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. Web ðï ࡱ á> þÿ ‡ þÿÿÿþÿÿÿ ‚ ƒ. Is the shop environment uncluttered? 6s audit tool for printing.xlsx get 6s audit tool for printing.xlsx.

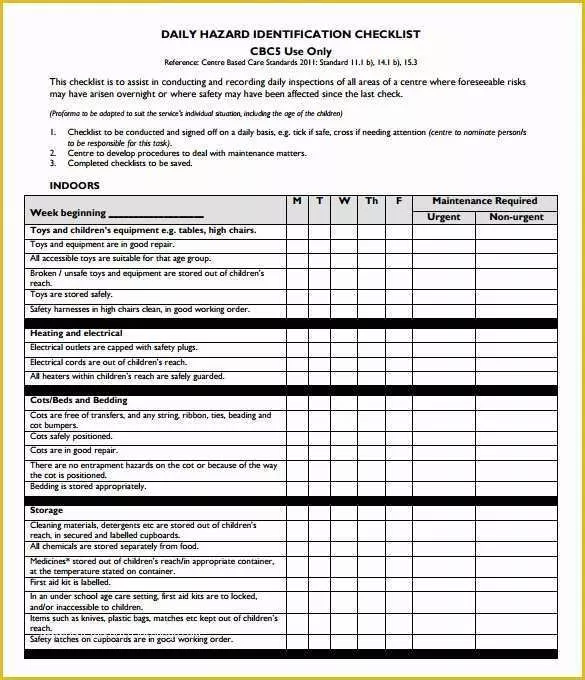

Id Template Free Of 6s Daily Checklist Templates to Pin On Pinterest

Web home | association for manufacturing excellence Is the shop environment uncluttered? Web a 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. 6s (otherwise known as 5s + safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a. Take a photo.

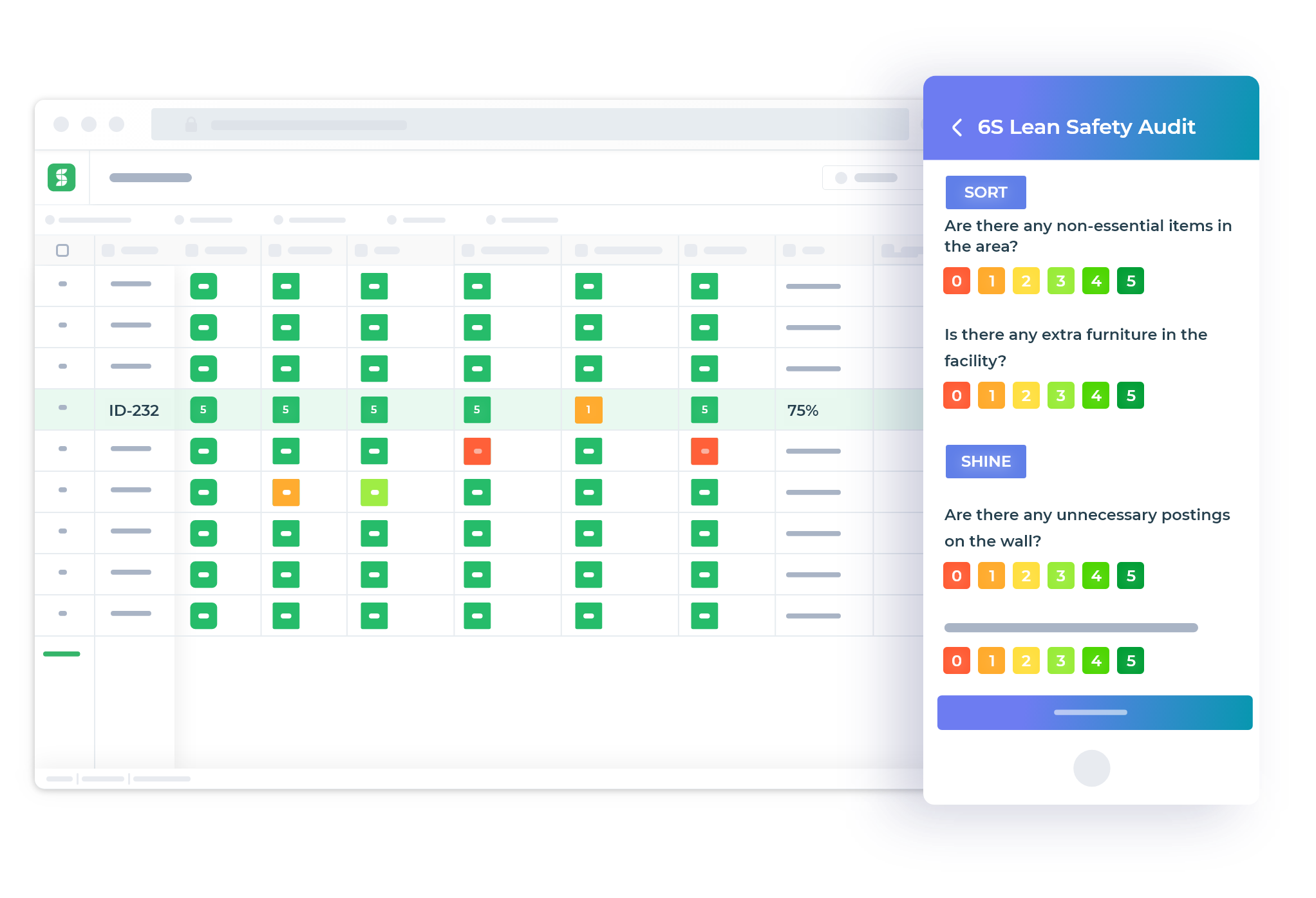

6S Audit Checklist DronaHQ LowCode Platform

Take a photo of steps or activity conducted and. By applying the 6s’ you will organize, eliminate unneeded materials and. Is the shop environment uncluttered? Separate out what is needed for the operations. The templates available in our public library have been created by our customers and employees to help get you started.

6s Audit Form, Rev. 1.xlsx ReadOnly Willington Nameplate

Web 6s is a method used to create and maintain a clean, orderly, and safe work environment. Is the shop environment uncluttered? Browse the public library of over 100,000 free editable checklists for. Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement. Web a 6s audit checklist manufacturing is a powerful tool.

Copy of 6s Audit Checklist Personal Protective Equipment Safety

Is the shop environment uncluttered? 6s (otherwise known as 5s + safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a. Web 6s is a method used to create and maintain a clean, orderly, and safe work environment. By applying the 6s’ you will organize, eliminate unneeded materials and. 6s stands.

6S Audit Report No.4 Inventory Recycling

Ad draw control charts, histograms, paretos, and fishbones in seconds. Web 6s is a method used to create and maintain a clean, orderly, and safe work environment. Browse the public library of over 100,000 free editable checklists for. Web home | association for manufacturing excellence Take a photo of steps or activity conducted and.

6S Checklist Format format Excel PDF Sample

Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management with examples,. 6s stands for sort, simplify, sweep, standardize,. Common examples of checklists are: Web a 6s audit checklist for manufacturing is a powerful tool that can help companies improve efficiency, safety, and workplace organization. Use this template periodically to inspect.

Is the shop environment uncluttered? Web a 6s audit is basically a 5s audit with extra attention to safety. Web 6s is a method used to create and maintain a clean, orderly, and safe work environment. Web a 6s audit checklist for manufacturing is a powerful tool that can help companies improve efficiency, safety, and workplace organization. Ad draw control charts, histograms, paretos, and fishbones in seconds. Separate out what is needed for the operations. Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement. Web 6s safety checklist with the help of this 6s safety checklist, you can identify hazards or potential risks while executing tasks in the workplace. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics. 6s stands for sort, simplify, sweep, standardize,. Web this 6s audit sheet can be used to evaluate and improve your organization and the cleanliness of your workspace. Common examples of checklists are: Ad draw control charts, histograms, paretos, and fishbones in seconds. Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management with examples,. 6s (otherwise known as 5s + safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a. Take a photo of steps or activity conducted and. Web pdf template, use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in the workplace. Browse the public library of over 100,000 free editable checklists for. Web ðï ࡱ á> þÿ ‡ þÿÿÿþÿÿÿ ‚ ƒ. The templates available in our public library have been created by our customers and employees to help get you started.

Web This 6S Audit Sheet Can Be Used To Evaluate And Improve Your Organization And The Cleanliness Of Your Workspace.

Common examples of checklists are: Ad draw control charts, histograms, paretos, and fishbones in seconds. Browse the public library of over 100,000 free editable checklists for. 6s stands for sort, simplify, sweep, standardize,.

The 6S System Is Based On Six Key Areas:.

Ad draw control charts, histograms, paretos, and fishbones in seconds. Is the shop environment uncluttered? Web home | association for manufacturing excellence The templates available in our public library have been created by our customers and employees to help get you started.

Use This Template Periodically To Inspect The Quality And Safety Practices In Your Manufacturing, Logistics.

6s audit tool for printing.xlsx get 6s audit tool for printing.xlsx show details how it. By applying the 6s’ you will organize, eliminate unneeded materials and. Take a photo of steps or activity conducted and. Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management with examples,.

You Can Take A Photo Of The Steps.

6s (otherwise known as 5s + safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a. Separate out what is needed for the operations. Web ðï ࡱ á> þÿ ‡ þÿÿÿþÿÿÿ ‚ ƒ. Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement.